Sino-Italian Joint Research Laboratory on Prognostics and Health Management for Intelligent Maintenance (PHM-IM)

Sino-Italian Joint Research Laboratory on Prognostics and Health Management for Intelligent Maintenance (PHM-IM) was jointly established by Professor Kang Rui from Beihang University and Professor Enrico Zio from Politecnico di Milano, with Associate Professor Yang Hu serving as the Executive Director.

The laboratory adheres to the overall philosophy of “cyber-physical integration, intelligence-driven development, and system empowerment”, focusing on research in Prognostics and Health Management (PHM), system modeling and simulation, intelligent maintenance, and multimodal large models for complex engineering systems.

It forms a complete research chain that runs through “model – algorithm – simulation – verification – application”, providing a multidisciplinary experimental platform for PHM and intelligent maintenance of high-end equipment in the fields of aerospace, energy and transportation, and advanced manufacturing.

The laboratory currently consists of 2 professors, 2 associate research fellows, 1 associate professor, 3 postdoctoral researchers, and 13 graduate students.

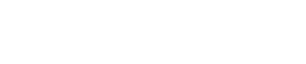

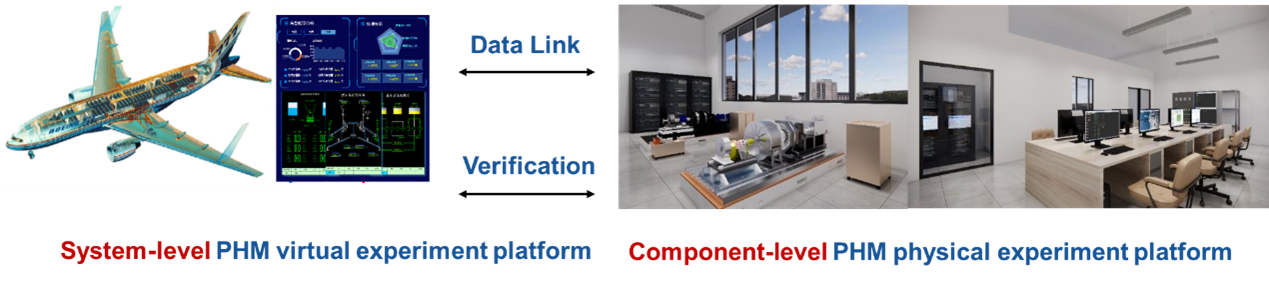

The laboratory is composed of 4 core modules, forming a cyber-physical integrated experiment platform for PHM and intelligent maintenance:

PHM Simulation System:

Capable of simulating Airbus A320 and Boeing 737 aircraft, covering 12 key subsystems and more than 300 critical flight parameters.

It supports fault injection at the LRU, equipment, and subsystem levels, as well as flight environment modeling and data generation, serving for PHM algorithm validation and maintenance strategy verification.Physical Fault Experiment Platform:

Simulates typical fault modes of on-board components and equipment such as gearboxes, bearings, electromechanical systems, and pumps.

It is equipped with a dynamic torque sensor (accuracy: 0.01 Nm) and a hydraulic loading system (maximum load: 50 kN), enabling experiments on degradation mechanisms and fault evolution processes.Virtual Fault Experiment Platform:

Includes a fault logic database, sensor virtual injection module, and an on-board data bus simulator.

It can simulate the operating data of airborne equipment under both normal and typical fault conditions; after bus-level processing, the data can be transmitted in real time to the PHM simulation system, realizing multi-level simulation from signal anomalies to system-level failures.High-Performance Computing and Algorithm Platform:

Equipped with a 128-core CPU, 1 TB of memory, and a GPU cluster containing multiple NVIDIA A100 cards,

it supports pre-training, fine-tuning, and inference of multimodal large models, providing powerful computational resources for intelligent diagnostics, reinforcement learning–based decision-making, and digital twin simulations.

Based on its cyber-physical integrated architecture, the laboratory supports 3 typical experimental modes:

Mechanism Research Experiments:

Based on real operational and degradation data, these experiments study the failure mechanisms and lifetime prediction laws of key components.Cyber-Physical Integrated Experiments:

Combine simulated fault data with real operational data, using digital twins and simulation systems to verify the robustness and generalization capability of PHM algorithms.Fleet-Level Operation/Maintenance Experiments:

Integrate PHM with fleet operation and maintenance simulation platforms to study maintenance decision-making, task assignment, and resource allocation optimization, and to evaluate the overall operational efficiency of equipment fleets under different strategies.

At present, the laboratory has established a long-term collaboration with ZheJiang Loong Airlines CO.,Ltd, acquiring over 10 years of A320 fleet operational data—more than 150,000 flight cycles and over 2,000 real maintenance work orders.

It also collaborates with the Aviation Industry Corporation of China, China State Shipbuilding Corporation, Huawei 2012 Laboratories, and the China Electronic Product Reliability and Environmental Testing Research Institute, conducting joint research on PHM and intelligent maintenance of high-value equipment.

Meanwhile, the laboratory shares resources with the Sino-French Dassault Excellence Center, Reliability Digital Twin Laboratory, and Fleet Operation and Maintenance Simulation Laboratory at the Smart Civil Aviation Innovation Center of Beihang Hangzhou International Innovation Institute, enabling end-to-end collaboration across the entire process of system design, modeling, simulation, and verification for complex engineering systems.