|

Supervisor of Master's Candidates

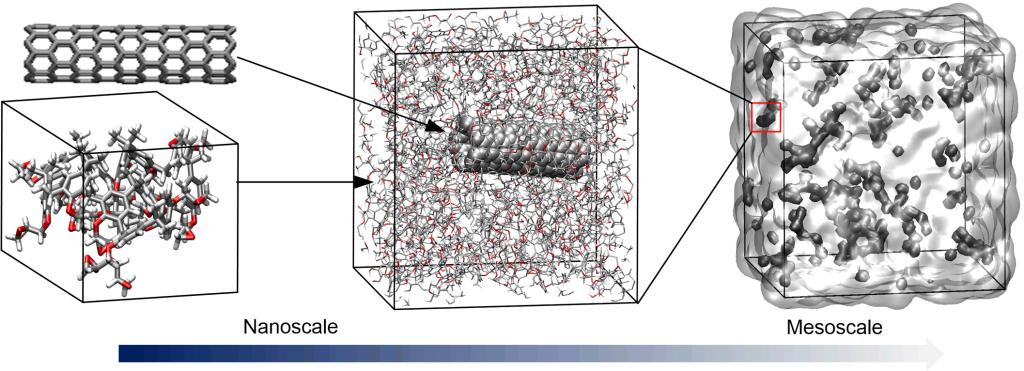

Micromechanics of polymer composite

Polymer composite can be readily found in applications across multiple length scales, ranging from nanoscale structures such as photoresist lithography in microelectronic system, to macroscale applications such as composite components in aerospace, automotive, and civil engineering. It is one of the great challenges of providing the bottom-up prediction of the structure and properties of polymer composite at these multiple scales. To address this issue, a multiscale approach is developed to construct the atomistic network and to coarse-grain the cross-linked structure, enabling the prediction of the mechanical behaviors from nano- to mesoscale. The developed multiscale approach provides the versatile tool to link the nano-level mechanical behaviors to the macro-level durability issue.

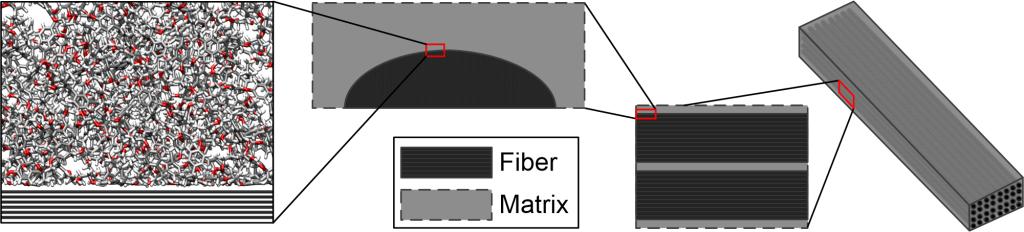

Failure mechanism of FRP composite

Fiber-reinforced polymer (FRP) composite possesses outstanding properties, which has found increasing applications in transportation infrastructures and civil engineering field, especially in the marine and offshore structures. There has been an increased awareness of composite degradation under environmental exposures, which is directly related to the deteriorated bonding property between fiber and matrix, as it controls the stress transfer between adjacent fibers. To explore the interfacial degradation mechanism, we have developed a molecular modeling framework for understanding the microscopic behavior of fiber/matrix interface under exposure to various environmental conditions. Our results provide the microscopic information of interfacial deterioration in FRP composite under environmental exposures, which forms the basis for developing the multiscale framework to characterize the degradation of FRP composites.

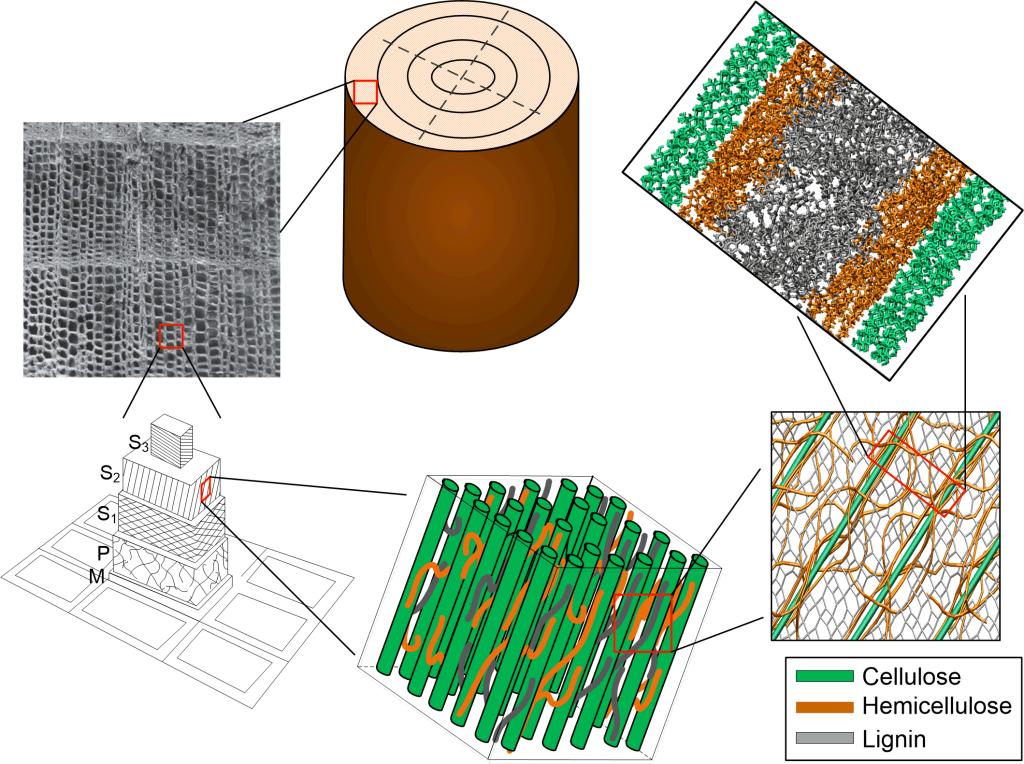

Micromechanics of bamboo/wood materials

The hierarchical structure of plant material along with its supremacy in mechanical behavior has made it a proficient template for bio-mimicking purposes to design bio-inspired structural materials with desired properties. As the plant cell wall plays an important role in the load bearing, an in-depth understanding of the interplays between the structure and properties of cell wall microstructure is at the heart of producing futuristic materials with tunable properties. Using molecular modeling, our researches have explored the viscoelastic and mechanical behaviors of the constituent polymers in bamboo cell wall, and uncovered that the mechanical behaviors of cell wall constituents and their interactions play an important role in the mechanical response of the overall cell wall microstructur. The work provides the guideline to assemble or engineer the basic constituents and modify the structure to produce bio-inspired materials with specified properties.